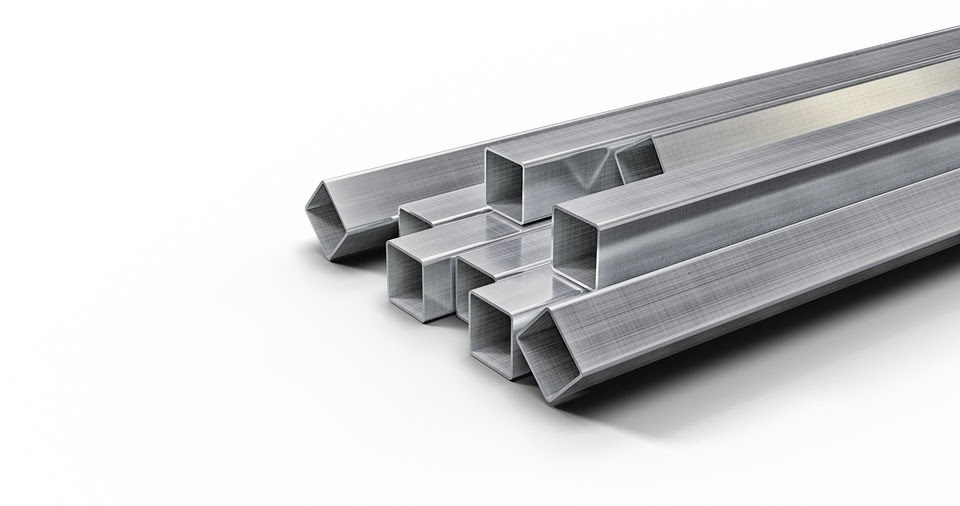

Factors to Consider when Selecting Best Material for Sheet Metal Fabrication

Sheet metal is an essential material in the manufacturing industry as most companies mostly use it for various processes. Therefore, it’s crucial to consider the sheet metal companies use. The sheet metal companies require metal fabrication consisting of copper, titanium, brass, and tin.

For you to achieve the best metal fabrication, it’s important to choose suitable materials. However, the materials have various properties like width and shapes and others to choose from, presenting a challenging task to choose the appropriate material. This article provides an insight into the factors the South East Asia Sheet Metal Company advises for selecting the ideal material for the fabrication process.

1. Consider the hardness of the material

The material’s hardness relates to the ability of a material to withstand deformation when you apply any force on it. You can measure the hardness based on resistance to scratches, bounces, and indentations. It’ll be good if you choose hard materials because they can withstand load and abrasion. The best metals with high hardness levels are bronze, titanium, steel, and brass.

2. The proper use and end products

Before choosing the materials, it’ll be essential to have objectives on how well you’ll use the product. Thus, how you intend to use the product will significantly affect the type of materials you need. Additionally, think about the product your components will interact with well, and choose the suitable material for them.

3. Corrosion resistance

It’s important to consider the conditions the material will be exposed to while choosing it. Some materials will react better to water, oxidation, and other elements than other materials. Thus, it would be essential to choose less-corrosive materials, such as copper, aluminum, nickel, and carbon steel. The South East Asia Sheet Metal Company uses less corrosion-resistant metals to achieve top-quality products.

4. The cost of the material

The material’s cost is significant when choosing suitable metal for metal fabrication. It’s good to identify the list of materials that are suitable for your needs. Then have a list of the prices for the various metals and their quality. Most experts advise you to go for quality over price; however, it’ll be good to watch what you need to spend. Lastly, before making any decision check the number of times, the lower-cost material will require additional materials compared with high-cost metals.

5. The importance of the materials

While selecting the material, you’ll need to identify the importance of the material in the process. Why do you need to have the product in the process? What will the product look like without the materials in the process? Thus, only select the important materials for the process and provide the product with competitive advantages such as endurance, functions, and mechanical properties.

Conclusion

Choosing the right material for sheet metal fabrication is a huge step in achieving improved and more efficient products resulting from the fabrication process. Thus when looking for the suitable material for fabrication, South East Asia Sheet Metal Company considers the factors above. These factors are essential for leading a manufacturer to choose the right metal for fabrication.